Introduction

The automotive industry is increasingly adopting virtual testing methods to streamline vehicle development. Traditional sequential development cycles are being replaced with advanced simulation solutions that reduce costs and accelerate innovation. At the forefront of this shift is VI-grade, whose state-of-the-art simulators and cloud-based platforms empower engineers to refine designs digitally before physical prototypes are ever built.

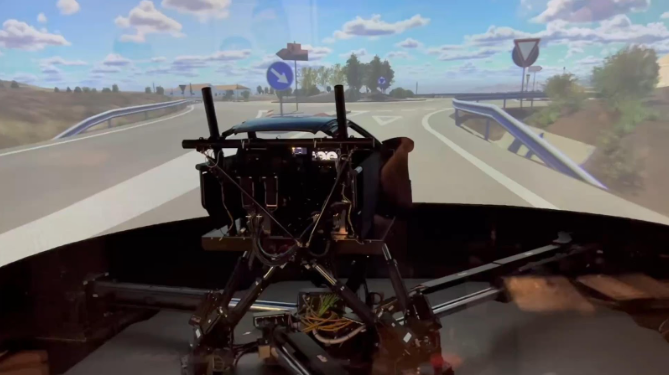

Attendees at the 2025 North American Zero Prototypes Day event got a chance to use VI-grade’s simulators. (Image: VI-grade.)

Embracing Zero Prototypes

Central to this transformation is the “zero prototypes” philosophy. At VI-grade’s recent Zero Prototypes Day event in Novi, Michigan, industry experts showcased how virtual testing complements physical testing. According to Guido Bairati, VP at HBK and former managing director at VI-grade, “the driving simulator has the great advantage of putting the driver in the loop into the equation, so you can easily test your component with a real driver.”

Companies such as Hitachi Astemo leverage VI-grade’s Full Spectrum Simulator (FSS) to validate AI-based damper models virtually. Omar Elsewify of Astemo notes the increased expectation from OEMs for suppliers to provide comprehensive validation solutions, including hardware-in-the-loop and driver-in-the-loop simulations.

Cutting-Edge Simulation Technologies

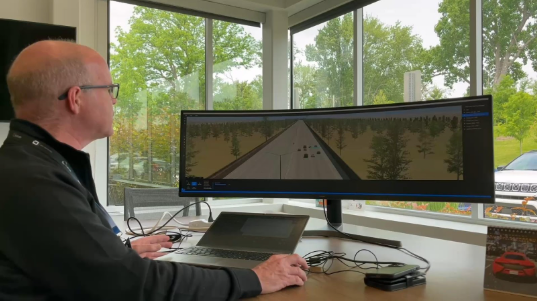

VI-grade’s innovative tools, such as the Driver-in-Motion Full Spectrum Simulator (DiM FSS), offer realistic, multi-attribute testing capabilities. Recently, VI-grade introduced the HexaRev simulator, featuring a six-degree-of-freedom motion system designed without gears or belts, which ensures quieter and immediate responses. Dave Bogema, senior director at VI-grade, highlights HexaRev’s ability to provide a significantly larger motion envelope compared to traditional systems.

Screenshot from VI-grade’s HexaRev demo video featured by Engineering.com.

Watch the full video here: engineering.com → Virtual Testing Article

Enhancing Human-Centric Design

Virtual testing is also pivotal for evaluating human-machine interfaces (HMIs). VI-grade’s Compact HMI simulator allows real-time assessment of different cockpit configurations. Bogema emphasises the necessity of driver feedback: “It’s the driver who decides whether that HMI is good enough.”

Further enhancing the human element, Harman Becker Automotive Solutions utilises VI-grade’s NVH simulator to refine audio algorithms interactively. Engineers globally can tune sound features in real time, dramatically speeding up product iterations.

Data-Driven Development and AI Integration

With growing complexities in vehicle design, the management of simulation data becomes critical. VI-grade’s VI-DataDrive Cloud addresses this by enabling parallel cloud-based simulations, significantly enhancing data processing capabilities. Bairati anticipates AI agents will soon assist engineers by analysing this extensive data, guiding the direction of future development.

However, caution remains essential. VI-grade’s Iain Dodds advises against over-reliance on AI without proper domain expertise, ensuring that conclusions drawn from data are both relevant and valuable.

Iain Dodds, VI-grade’s technical director in North America, demonstrates VI-WorldSim.

Screenshot from video by Engineering.com — Watch full video.

Conclusion

Virtual testing represents a fundamental shift towards agile, efficient automotive development. Although physical testing will not disappear, it is now primarily used to refine digital models, significantly shortening product development cycles. As simulation technologies evolve, the automotive industry will continue to benefit from faster innovation cycles, reduced costs, and more precise design validations, ensuring competitiveness in an increasingly demanding global market.

Partner with Alpinum

Alpinum helps automotive innovators accelerate time‑to‑market with expert strategies in digital prototyping and engineering excellence.

Whether you’re exploring zero‑prototype workflows or scaling AI‑enhanced testing tools, our team can help you tackle your next-generation vehicle development challenges.

Contact us today to discover how we can support your transformation.

Written by : Mike Bartley

Mike started in software testing in 1988 after completing a PhD in Math, moving to semiconductor Design Verification (DV) in 1994, verifying designs (on Silicon and FPGA) going into commercial and safety-related sectors such as mobile phones, automotive, comms, cloud/data servers, and Artificial Intelligence. Mike built and managed state-of-the-art DV teams inside several companies, specialising in CPU verification.

Mike founded and grew a DV services company to 450+ engineers globally, successfully delivering services and solutions to over 50+ clients.

Mike started Alpinum in April 2025 to deliver a range of start-of-the art industry solutions:

Alpinum AI provides tools and automations using Artificial Intelligence to help companies reduce development costs (by up to 90%!) Alpinum Services provides RTL to GDS VLSI services from nearshore and offshore centres in Vietnam, India, Egypt, Eastern Europe, Mexico and Costa Rica. Alpinum Consulting also provides strategic board level consultancy services, helping companies to grow. Alpinum training department provides self-paced, fully online training in System Verilog, UVM Introduction and Advanced, Formal Verification, DV methodologies for SV, UVM, VHDL and OSVVM and CPU/RISC-V. Alpinum Events organises a number of free-to-attend industry events

You can contact Mike (mike@alpinumconsulting.com or +44 7796 307958) or book a meeting with Mike using Calendly (https://calendly.com/mike-alpinumconsulting).

Stay Informed and Stay Ahead

Latest Articles, Guides and News

Explore related insights from Alpinum that dive deeper into design verification challenges, practical solutions, and expert perspectives from across the global engineering landscape.